Product Categories

We manufacture a wide range of components from standard fasteners to complex custom designs.

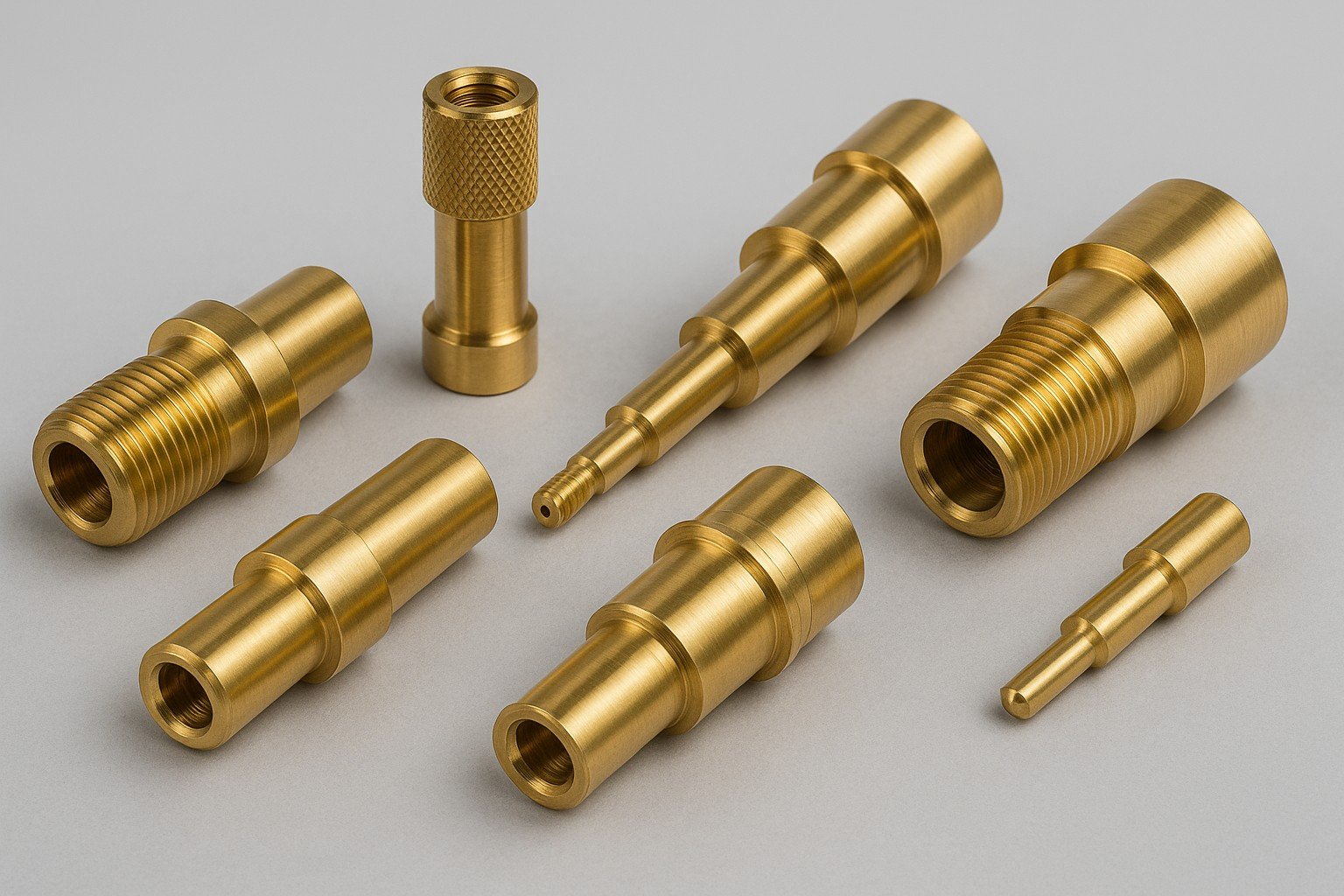

Brass Components

High-precision standard and custom brass components for diverse industrial applications.

View Details

Brass Turned Components

Precision turned brass parts manufactured using advanced CNC and automatic lathes.

View Details

CNC Turned Parts

High-precision CNC turned parts for critical engineering applications in automotive and aerospace.

View Details