Technical Specs

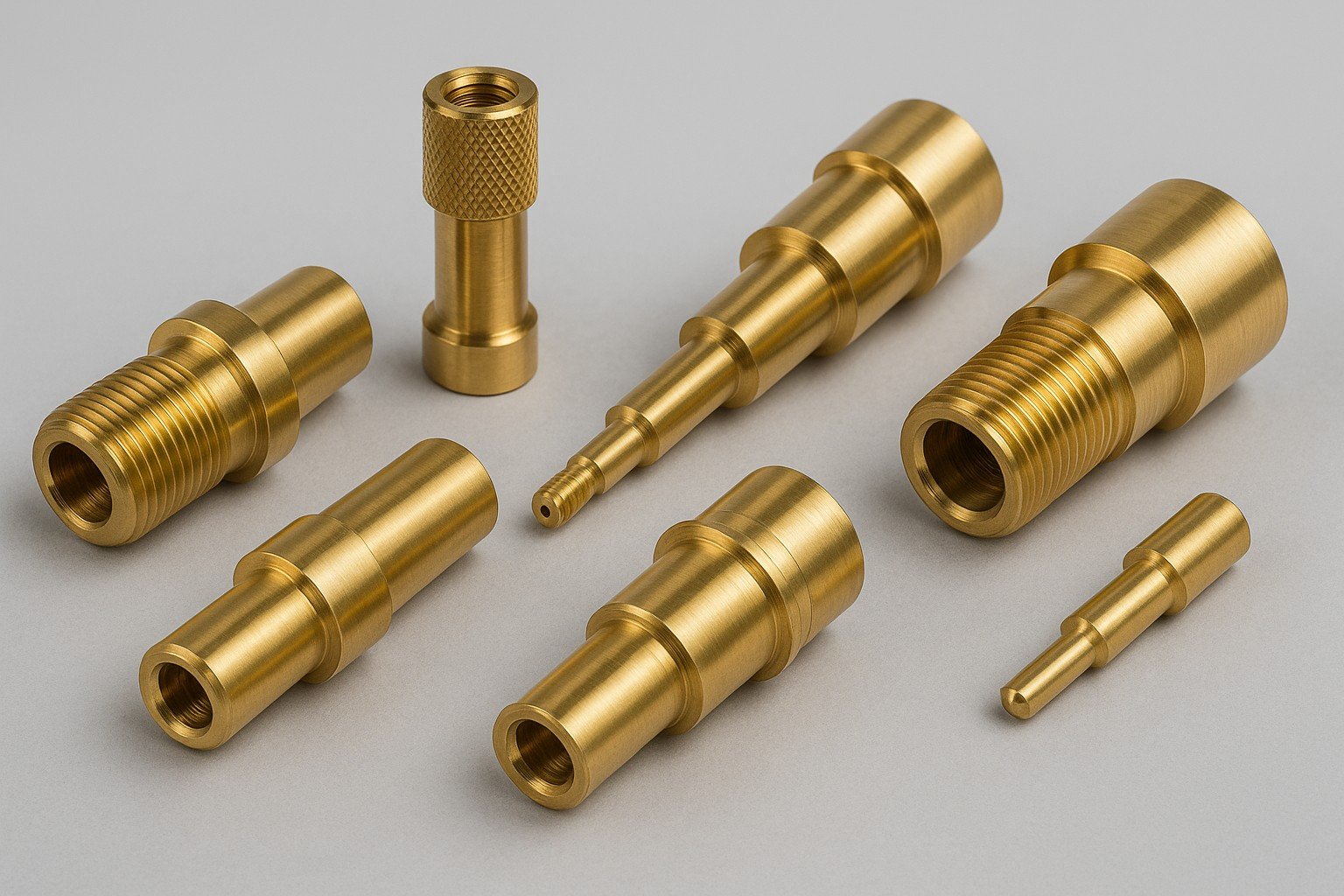

Brass Turned Components

Our Brass Turned Components are crafted with meticulous attention to detail using a fleet of high-speed automatic lathes (Traub) and CNC turning centers. This category covers a vast array of cylindrical parts including bushings, inserts, pins, and adaptors. By utilizing bar-fed mechanisms, we achieve high throughput with consistent quality, making us an ideal partner for high-volume OEM requirements. We maintain strict control over concentricity, circularity, and surface finish, ensuring that our turned parts fit perfectly into your automated assembly lines.

Key Features

- Exact Concentricity

- Mirror-like Surface Finish

- Cost-effective for high volume

- Burr-free edges

- Tight tolerance threads

Applications

- Fasteners & Inserts

- Automotive Bushings

- Electrical Connectors

- Plumbing Fittings

- Sensor Housings