Technical Specs

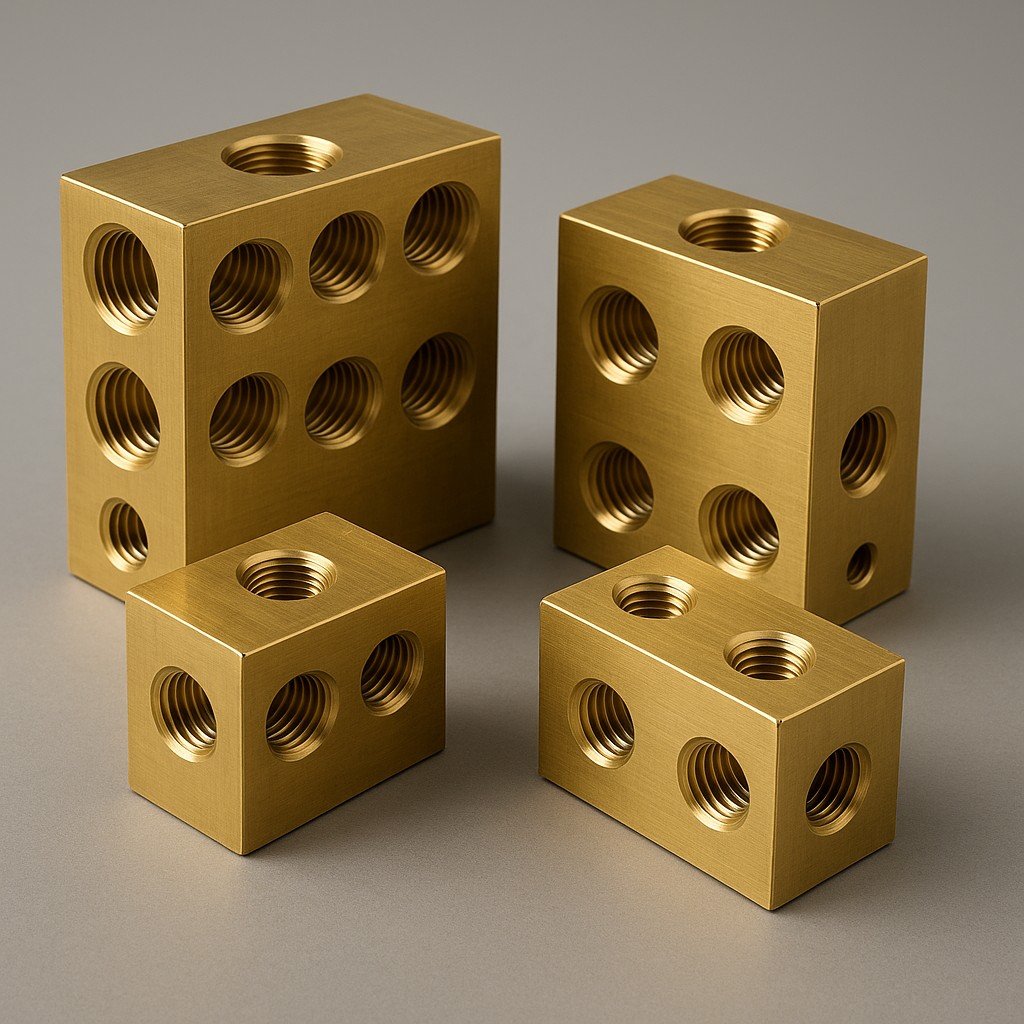

Brass Machined Components

We offer a wide array of Brass Machined Components that go beyond simple turning. These parts often require multi-axis machining, including complex milling of slots, flats, and contours, as well as off-center drilling and tapping. Our facility is equipped with Vertical Machining Centers (VMCs) and Drill-Tap centers to handle these secondary operations with high precision. We cater to industries requiring robust components like hydraulic valve bodies, pneumatic manifolds, and complex industrial fittings. Our CAD/CAM integration allows us to import your solid models directly and generate optimized toolpaths.

Key Features

- Complex Shapes and Contours

- Turn-Mill Integration

- High Structural Integrity

- Uniform Tolerances

Applications

- Hydraulic Valve Components

- Pneumatic Manifolds

- Medical Equipment Parts

- Industrial Hardware